Chaise Lounge prototype for Deloss Webber

A minimal steel chair frame optimized for a woven seat, and low volume production. I was hired by Seattle artist Deloss (Del) Webber to turn his concept sketch into a dimensioned drawing that could be built & tested. The goal was to use the lightest tubing we could, without adding additional manufacturing challenges specific to very thinwall tubing.

The side profile was bent, and a lot of things in my small shop were moved so that the tube could swing around! My tube bender, a Di-acro #3 was well suited to this job and made quick work of the bending.

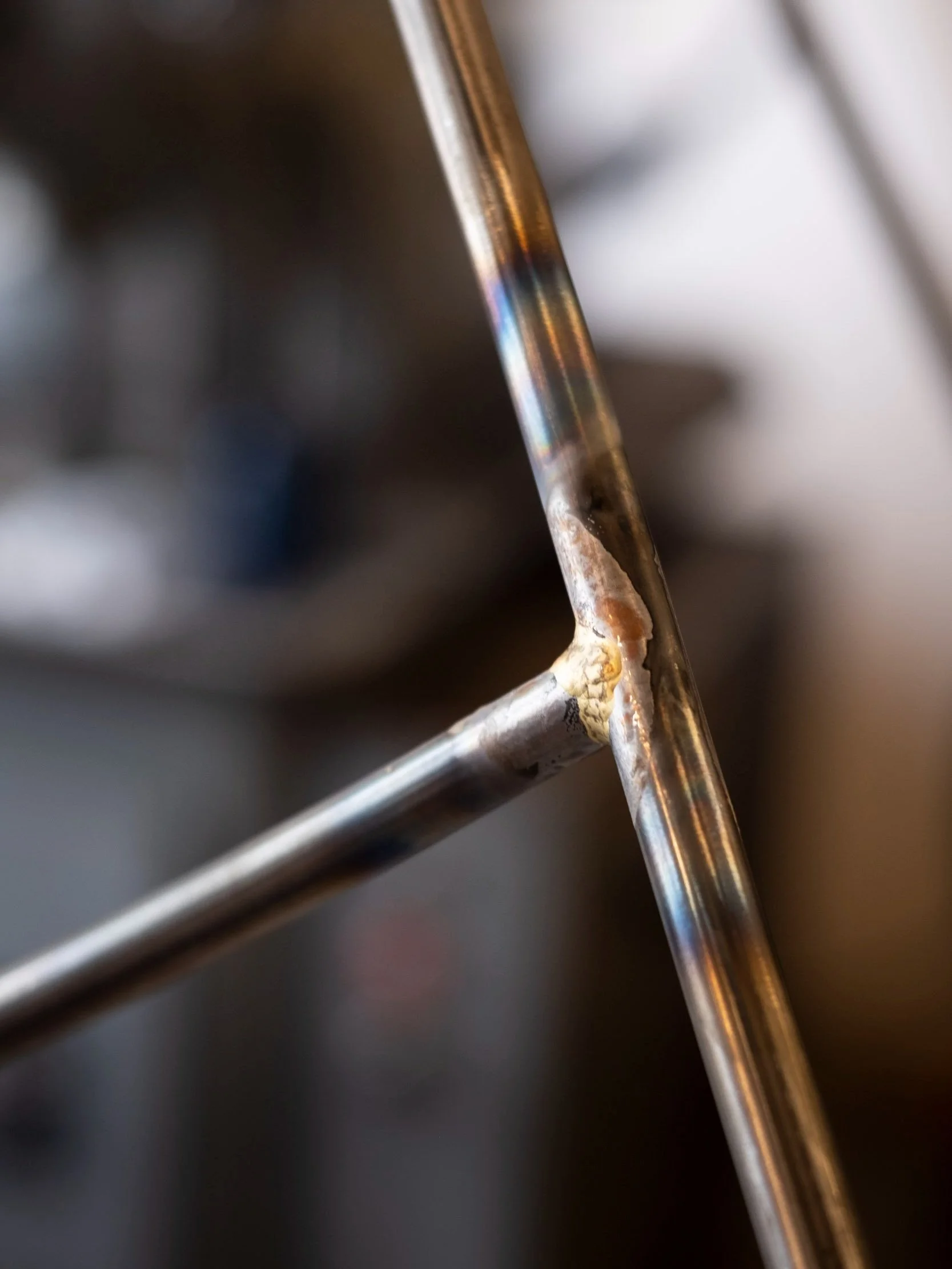

After making the two sides, I then brazed them together with low fuming bronze. Brazing was nearly as quick as TIG welding in this case, and resulted in smooth joints that worked well with the weaving terminations and aesthetics of the piece.

Ultimately the structure ended up being a little too flexible - we had found the limits of our design & material!

Del’s chair was a great exercise in tube bending, and incorporating the unfamiliar process of Rattan weaving into my design. I first made the side profile of the chair as two identical halves to be welded together with braces that also act as anchor points for the weaving. I sketched the braces out later, in conversation with Del to determine the ideal placement for weaving.

Del’s studio team cut and repositioned the rear chair legs, and added a brace underneath the seat. Version 2 (below right) was able to hold a 200 lb. person with a very comfortable amount of flex.